Pipes

Pipes

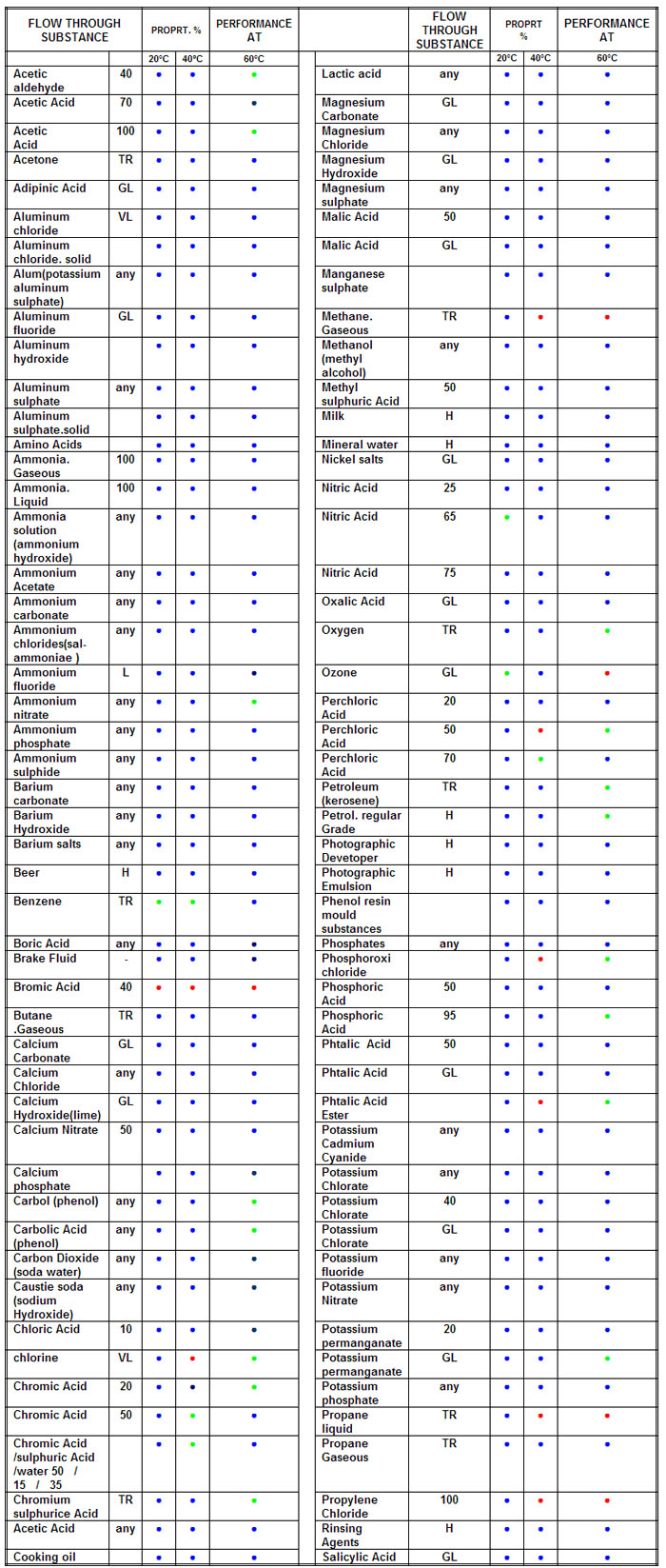

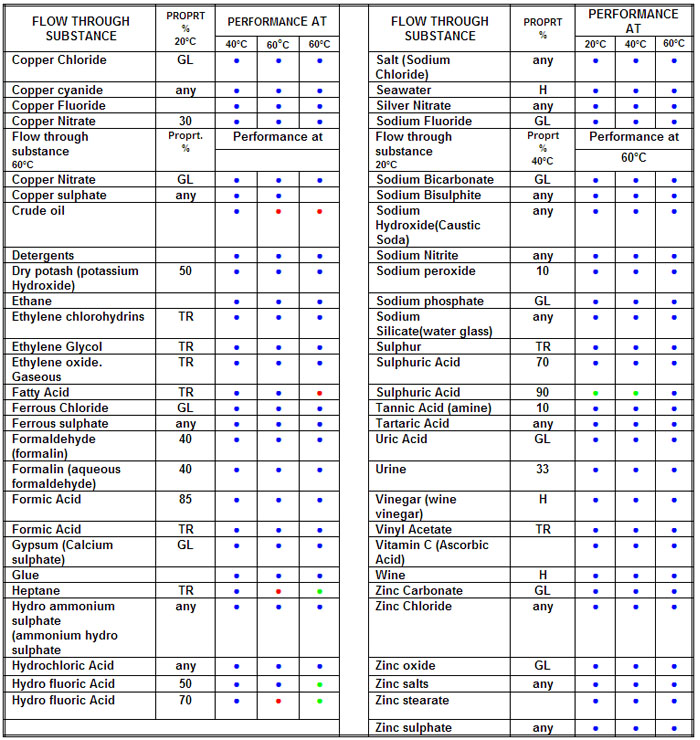

chemical resistance list

Explanationand interpretations of the material to resist List

The table includes some of the icons and shortcuts to demonstrate the installation of barriers and their effects during force inside polyethylene pipe.

% Percentage Refer To Mass Proportions In % VL Aqueous Solution, Mass Proportion > 10 % GL Aqueous Solution, Mass Proportion < 10 % Aqueous Solution, Started At 20 TR Chemical Is At Least Technically Pure H Normal Commercial Composition S Traces > 0.1 % G Usual Mass Proportion of Any Started Solution of Dilution Mechanical and physical propertiesfor Pipes of Polyethylene PE 80, which are produced by Misr ELnour Company

Mechanical and physical propertiesfor Pipes of Polyethylene PE 100, which are produced by Misr ELnour Company

|